The single tube system (STS)

The single tube system (STS)

The first choice for high productivity

The Single Tube System is based on external cutting fluid supply and internal chip transport.

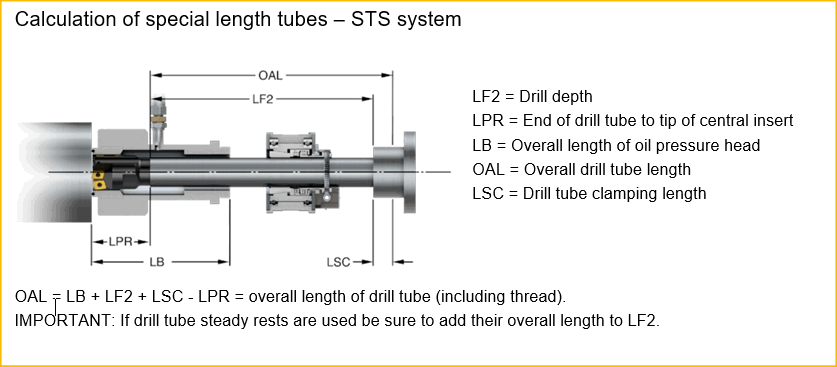

As a rule, the drill head is screwed onto the drill tube.

The cutting fluid is supplied via the space beween the drill tube and the drilled hole. The cutting fluid is then removed along with the chips through the drill tube.

The velocity of the cutting fluid is so high that chip transport takes place through the tube without disturbance.

Since chip evacuation is internal, no chipflute is required in the shank, so its cross-section can be made completely round, which provides much higher rigidity than in the gun drill system. The productivity of STS drilling is up to 6 times higher than for gun drilling.

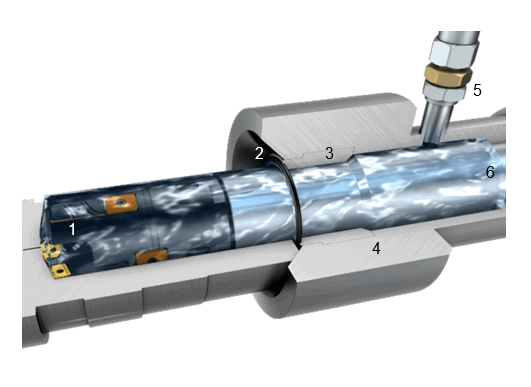

- Drill head

- Seal

- Drill bushing

- Oil pressure head

- Inlet for cutting fluid

- Drill tube

- In materials with poor chip forming properties such as stainless steel, and low-carbon steel.

- In materials with an uneven structure when chip breaking problems exist.

- More advantageous for long-series production.

- Uniform and extremely long workpieces.

- Requires special deep hole drilling machine.

- Drill tubes should be stored in a horizontal position in order to protect the thread areas where the material properties are thin.

Function

STS is based on external cutting fluid supply and internal chip transport. The drill head is attached to a cylindrical drill tube with a diameter that leaves a space between the hole being drilled and the drill tube.

The cutting fluid is supplied via the space between the drill tube and the drilled hole, while the cutting fluid pressure flushes the chips back out through the drill tube. The high cutting fluid velocity gives a very fluent chip transport.

Thanks to the internal chip evacuation, chip flutes are not required. The cross section can be made completely cylindrical, providing much higher rigidity than in the gun drill system.