How to reduce guide pad breakage in BTA drilling?

Guide pad breakage is a common problem in BTA (Boring and Trepanning Association) drilling that can lead to tool failure and downtime.

Here are some tips to help reduce guide pad breakage in BTA drilling:

Check for tool wear: Worn tools can cause guide pad breakage. Regularly check for tool wear and replace the tool when necessary. Worn tools can also cause vibration, which can lead to guide pad breakage.

Use appropriate cutting fluid: Cutting fluid can affect tool life and guide pad breakage. Use a high-quality cutting fluid and ensure that the fluid reaches the cutting zone. The fluid should provide sufficient lubrication to the guide pads and reduce heat buildup.

Optimize the cutting parameters: The cutting parameters, including the cutting speed, feed rate, and depth of cut, can affect guide pad breakage. Use appropriate parameters based on the material being drilled, the tool geometry, and the required surface finish. Avoid using excessively high cutting parameters, which can cause overheating and excessive wear on the tool and guide pads.

Ensure proper alignment and clamping: Improper alignment and clamping can cause guide pad breakage. Ensure that the work piece is properly aligned and clamped, and that the drill is in the correct position. Check for any interference between the drill and the work piece.

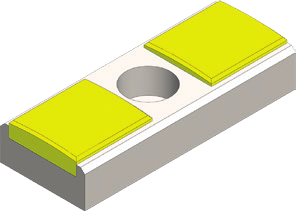

Use appropriate guide pads: The type of guide pad used can affect guide pad breakage. Choose BTA BORE’S DLC coated guide pads made of high-quality materials that can withstand the drilling forces and heat. Use guide pads with appropriate diameter and length that fit the drill and work piece.

Monitor the process: Monitor the drilling process continuously and check for signs of guide pad breakage. If guide pad breakage occurs, adjust the cutting parameters, coolant pressure, and flow rate, and check for proper chip evacuation.

In summary, reducing guide pad breakage in BTA drilling involves checking for tool wear, using appropriate cutting fluid, optimizing the cutting parameters, ensuring proper alignment and clamping, using appropriate guide pads, and monitoring the drilling process. By following these tips, you can reduce guide pad breakage and increase the tool life and productivity of the BTA drilling process.